Brew In A Bag (BIAB) is a great way to start all grain brewing.

You need very little equipment and the results are great. Some brewers will say it produces inferior beer to traditional all grain methods, but they’re just jealous.

Let’s start with a recipe on BeerSmith. You can also just purchase a pre made mash kit from most of the Homebrew shops.

| Grain Bill | |||

| 5.5kg | Pale Malt (2 Row) UK (5.9 EBC) Grain | 82.7 % | |

| 0.5kg | Caramel/Crystal Malt – 20L (39.4 EBC) Grain | 7.5 % | |

| 0.5kg | Munich Malt (17.7 EBC) Grain | 7.5 % | |

| 0.15kg | Roasted Barley (591.0 EBC) Grain | 2.3 % | |

| Mash Profile | Mash Temp | ||

| Saccharification | Add 31.96 l of water at 73.4 | 68.9 C | 60 min |

| Mash Out | Heat to 75.6 C over 7 min | 75.6 C | 10 min |

| Hop Schedule | |||

| 75.00 g | Hallertau Perle [4.00 %] | 60 min | 27.6 IBUs |

| 1/2 tablet | Whirlfloc Tablet | 15 min | |

| 5 tsp | Yeast Nutrient | 15 min | |

| 80g | Challenger [6.00 %] | Steep/Whirlpool |

I add 32 litres of water to my boiler and bring the temperature up to 73°C.

While the “strike” water is heating I measure out my grains and run them through the mill.

I put the bag into the boiler when the temperature is up to 73°C. I put a colander into the base of the boiler first to keep the bag off the element. This will stop the element scorching the grain.

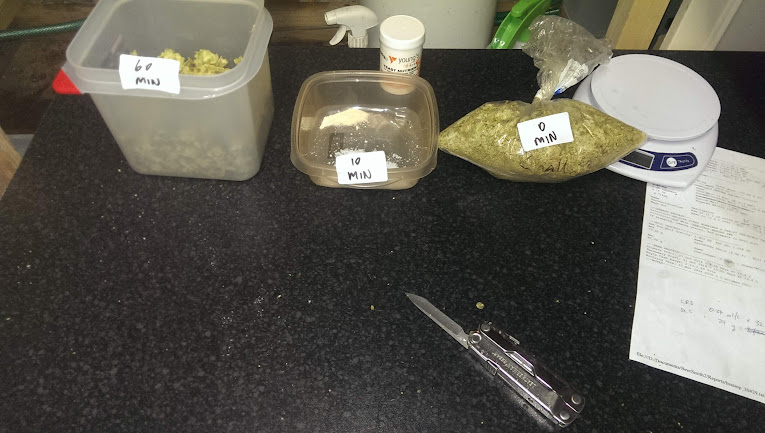

Now it’s time to mash-in. Just scoop in the grain slowly and stir gently to make sure there’s no dough balls. The high water to grain ratio in BIAB makes dough balls less of a problem. Gentle stirring prevents oxidation.

Make sure your temperature is good. I’m going for a malty beer so was aiming for a high mash temp (69°C ). It was close enough so I didn’t make any adjustments. I then cover the boiler with blankets and let it alone for 90 minutes. 60 minutes would probably be fine but I had another batch to bottle.

After the 90 minute rest, I take off the blankets and lid. Then I turn on the heat and bring it up to 76°C. Give it a few gentle stirs

while it’s heating up. Once I hit 76°C, I turn off the heat. Put the lid back on and let it rest for another 10 minutes. This step is what

AG brewers call a mash-out. Some say it’s not necessary when BIABing, but I like to do it. You need to heat the water up to a boil anyway.

The rest only adds about 15 minutes to the brew. It will make the mash less viscous which will give you more run-off.

When that’s done, it’s time to pull out the bag and collect the run-off. If you have any way of hanging the bag over the kettle it’s really handy. But you can just put the bag over a clean empty bucket to collect the run-off. I also twist the bag to squeeze that extra bit of juice out of it. Some brewers will tell you that squeezing the bag will produce unwanted tannins. Don’t listen to them, it’s a common brewing myth. Queeze the bag with a hydraulic press it want.

Turn the heat back on, you need to get it up to the boil now.

My boiler doesn’t have a hop strainer so I use the bag for this too. Just dump the grain, clean out the bag and put it back in the boiler.

As the wort is heating to the boil I get my hops and finings ready.

60 minute hops go in when you have a nice rolling boil.

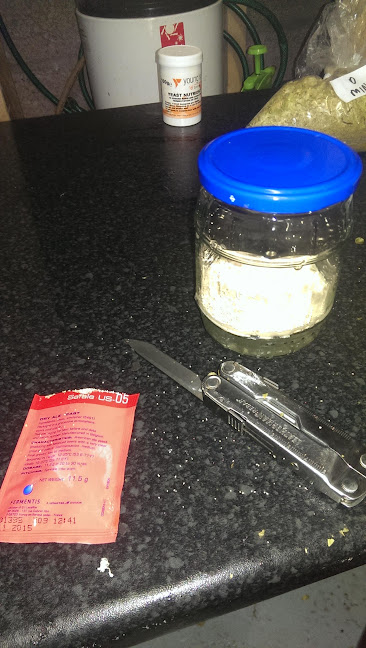

At 15 minutes to go, I put in the chiller to sanitise it. I also add my finings and re-hydrate the yeast.

Once the 60 minute boil is up, turn on the chiller. Then add the 0 minute hops. This is a good time to sanitise the FV.

After 15-20 minutes the wort is down to 20°C so I transfer it into the FV.

Pitch the yeast and stick on the air-lock.

Job done. I ended up with 23 litres in the FV. OG was 1.055°, 1 point low. Not bad!

Some FAQ’s:

Where did you get the bag?

I got mine from brewinabag.co.uk.

A lot of brewers just use a square of voile curtain material. I prefer a bag with handles myself, they are much easier to hang & twist.

You can make one yourself if you can work a sewing machine. More info here.

How much beer can I brew with my pot?

Boiler size required = Pre-boil volume + Grain absorption + grain volume

Most boilers lose 5 l/hr through evaporation

Pre-boil volume = final volume + 5 l = 23 + 5 = 28 litres

The grain absorbs about 0.611 l/kg

Grain absorption = 6.65 * 0.611 = 4.1 litres

Grain volume = 0.652 l/kg = 6.65 * 0.652 = 4.3 litres

Boiler size required = 28 + 4.1 + 4.3 = 36.4 litres

My boiler is ~40 litres.

Most new brewers use the 32 litre Peco boilers.

For a 19 litre batch I’d say she would be maxed out with around 6.5kg of grain.

That should still let you brew 19 litres of around 1.065° gravity without sparging.

Author: Garry