NHC Galileo Project

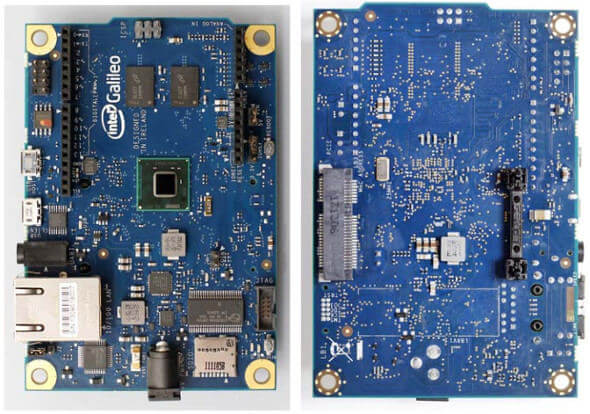

The recently announced made-in-Ireland Galileo singleboard computer came into my possession a few days ago. Tube had acquired a unit from Intel and after a callout to the membership, I volunteered to have a go at building a suitable project using the device and blogging about it as it happened.

The board itself is a sort of halfway house between a Raspberry Pi and an Arduino Uno R3. Under the covers it’s a Pentium class single core CPU running at about 400MHz running a trimmed down Linux.

Technical specs are available at http://www.intel.com/support/galileo/datasheet.htm if any are interested.

The board has lots of I/O but of particular note is the 10/100 Ethernet port. This will allow our project to include a web interface. Other I/O will allow us connect the Galileo to our brewing hardware for the purpose of monitoring and control.

In this blog, I will be describing the various stages in the development of a project which is useful to any home brewer. In choosing the project to build, the decision was based on how universally useful the result will be to the membership. If the project is useful and beneficial to all home brewers, that will be fantastic. Failing that, if it is useful to a significant fraction of the membership, that will be considered a good thing. If, on the other hand, the project is of interest and benefit to only a select few, this would probably rule it out as a candidate. Also of consideration is the overall project cost. Ideally we want a project that won’t require spending many hundreds of Euro’s on electric valves, expensive pumps or miles of plumbing. This last criterion would probably rule out attempting to build a HERMS or RIMS using the board (although the board would be well up for that).

My own preference is to build a temperature controlled fermentation chamber. Temperature controlled fermentation is, in the eyes of many, the single most effective thing a brewer can do to improve the quality and repeatability of their brews. It is, therefore, something that all brewers of all levels can make very good use of. The plan is that the power to a recycled freezer will be controlled by the Galileo. It will be switched on and off to regulate its internal temperature. Within will be placed one or more fermentation vessels each with a temperature probe submerged in the wort. A brew belt will be fitted around each fermentation vessel to allow increasing the wort temperature on very cold days or nights or when fermenting multiple brews that have differing temperature requirements.

Some of the membership already do this by using off-the-shelf temperature controllers such as the STC1000. These controllers can be had very reasonably and when combined with a freezer and a brew-belt are very effective at maintaining the interior of the brew at a set temperature for weeks at a time. So, given that these controllers are so cheap and easy to use why would a fermentation chamber be a good candidate project for the Galileo?

There are three things that standard temperature controllers cannot do that will differentiate this project. Firstly, they cannot regulate different temperatures for more than one beer in the same chamber. Secondly, they cannot, without manual intervention, have the regulated temperatures follow a profile over the duration of the fermentation. Thirdly, they can only be adjusted when the brewer is in the same place as the controller.

This project, which we’ll call the NHBC Fermentation Controller project, will be built using a recycled chest freezer or fridge and one brew belt for each fermentation vessel being controlled. Each FV will have its temperature monitored using digital temperature probes. The system is planned to provide the following capabilities when completed:

- Simultaneous temperature control of up to four brews. Each brew can be individually regulated to a temperature that differs from each of the others. Temperature control will use the PID methodology to avoid overshoots and undershoots.

- Each brew can have an individual temperature profile that can span any length of time. Each profile will define a temperature curve to be applied over that time span.

- Temperature range will be limited in the low end to that achievable by the freezer and in the high end by that reachable by the brewbelts. If the controller detects that the freezer is unable to lower the temperature to the required setting, or if the brewbelt cannot raise the temperature to that set, the system will send an email to the brewer warning them of the situation. It will then adjust the settings to the limits achievable to avoid burning out compressors or brewbelts.

- The project will have no hardware interface other than an on-off switch.

- The project user interface will be web based. Brewers will connect to their fermentation controllers by using a browser on their PCs or mobile devices (apologies to those brewers that do not have an internet connection).

- If someone wishes to write a mobile application instead, we can also expose a web services API but we’ll probably leave that for version 2.0 🙂

Once the cider season is behind me, I’ll get to procuring the bits and pieces needed for construction. As this likely to take a few weeks yet, If anyone has any input they’d like to contribute, now would be a good time.

/Justin Durkan